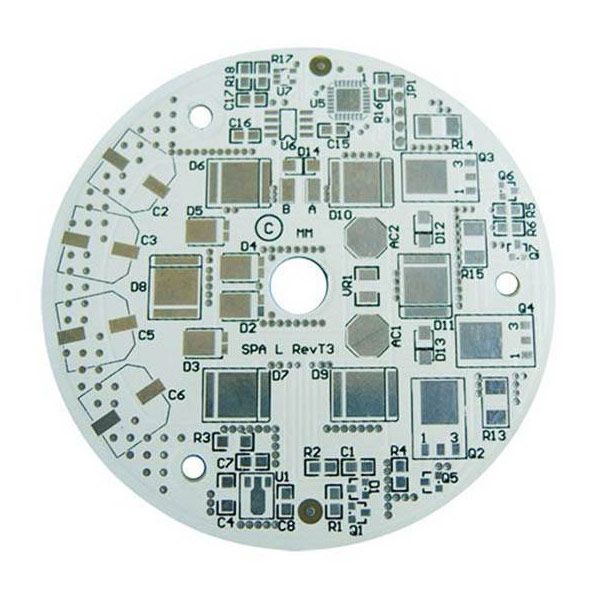

Printed Circuit Boards / PCB

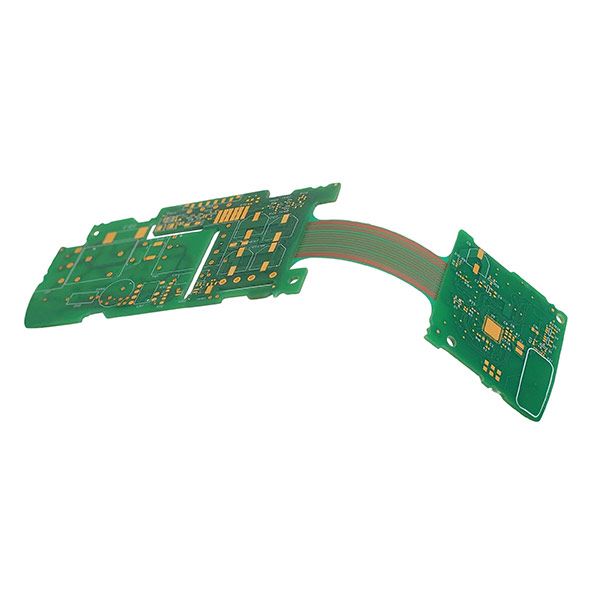

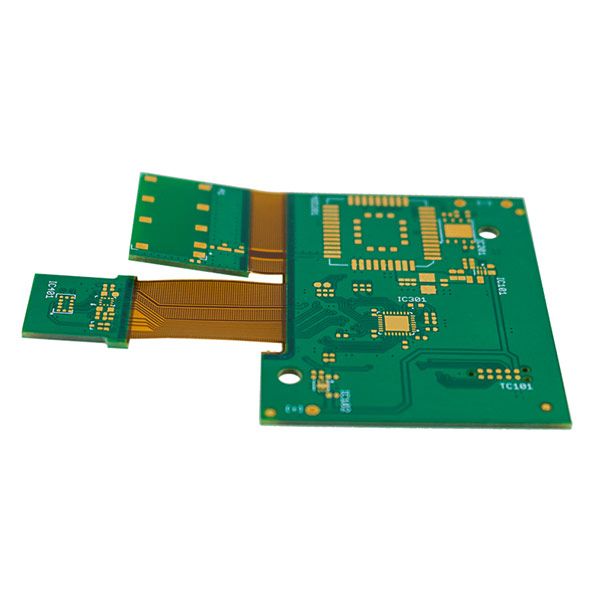

PCBs

PCBs, or printed circuit boards, are a key staple of modern electrical engineering. They can be found in almost every type of electronic device we use today. In fact they’re now so ubiquitous, it’d be much more difficult to list modern tech gadgets that don’t feature some form of PCB than those that do.

This quick introductory page covers the very basics of what printed circuit boards are, and how they’re put together. We’ll also outline the various services available through our state-of-the-art PCB design and manufacturing setup here at ABL Circuits.

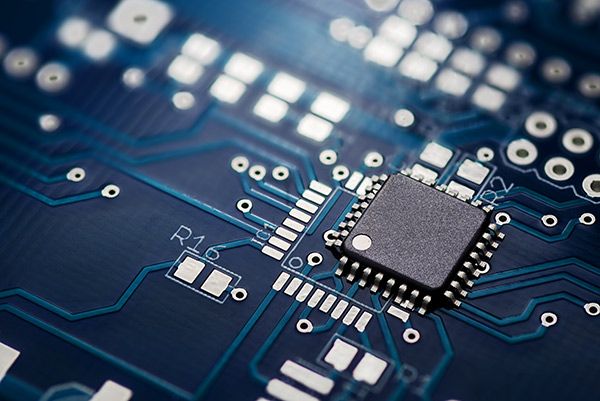

What is a PCB?

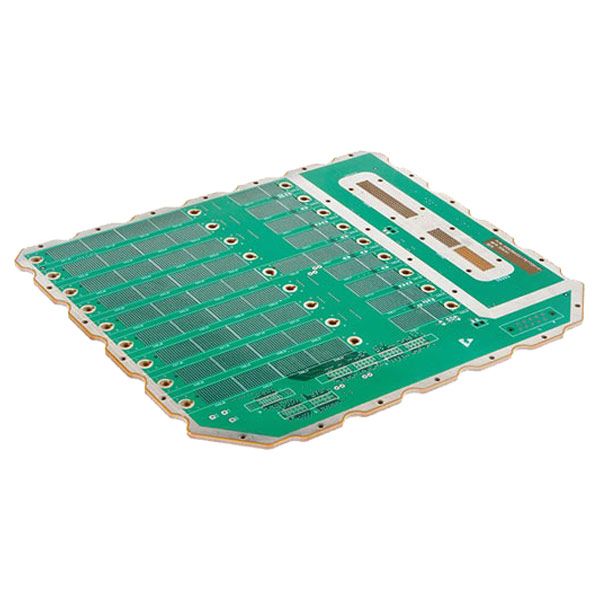

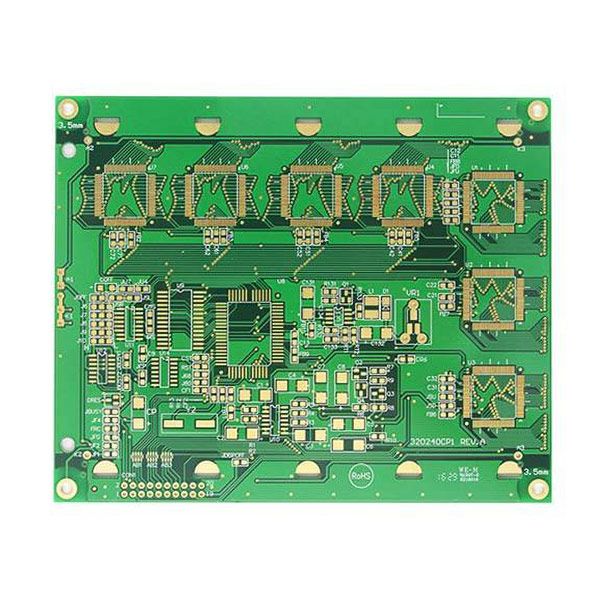

In very simple terms, a printed circuit board is essentially a neater, more compact and more reliable alternative to the older standard of multi-wire circuits. Before PCBs were as widely used as they are now, components in any electronic device relied on full point-to-point wiring for their interconnections.

Not only is this a labour-intensive and time consuming approach to circuit building, it’s also much more prone to various instabilities and points of failure. Shorts and faulty connections are risks very much inherent to those older circuit design standards, and the likelihood of encountering such issues only increases with device usage and age.

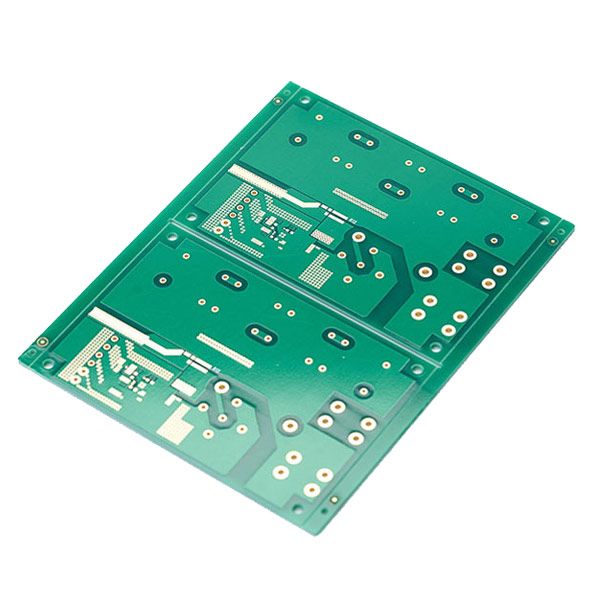

PCB Applications

PCB Process capability