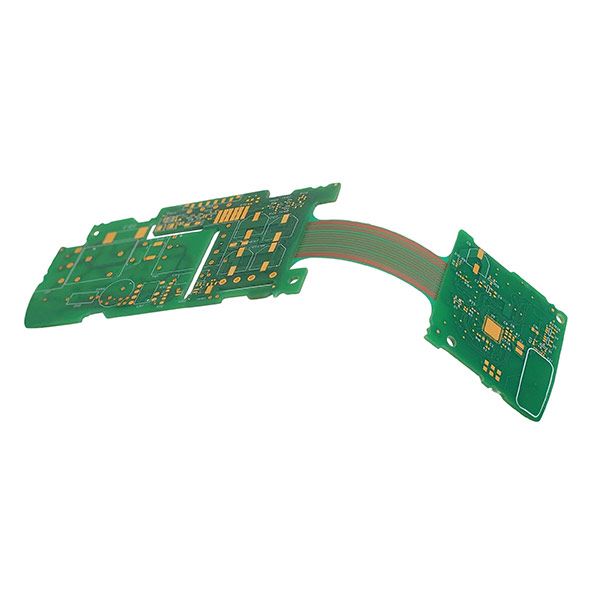

Semi-Flex PCB

What's the definition of a Semi-flex PCB?

Semi-flex PCBs are an ideal solution for mounting two PCBs in a unit at an angle. Instead of using connectors and cables or a composite flex-rigid PCB, users can design a single FR-4 semi-flex PCB that can be safely bent a sufficient number of times to allow installation and subsequent maintenance as needed.

Traditional rigid-flex PCB materials include rigid materials and flexible materials. The current production method is usually to carry on the pattern plating for the rigid substrates and flexible substrates, and then laminating the rigid substrates and flexible substrates together by using the adhesion agent. The materials of the adhesion agent are usually made of non-flowing prepregs. Flexible materials are expensive and costly to make. At present, the cost of multilayer rigid-flex PCB is 5-7 times of that of the traditional multi rigid PCB, which limits the development of rigid-flex PCB.

At the same time, compared with the rigid materials, the changes of flexible materials which will always change with the change of the size are much bigger. The inconsistency of expansion and contraction may lead to the circuit patterns’ dislocation of the same size rigid materials and flexible materials when laminating, which will reduce the reliability of the products.

Main Characteristics of Semi-Flex PCB

Low Cost

High Reliability

Special Installation Performance

Applications of Semi Flex PCBs

Semi flex PCBs are widely used in several applications. Due to the high reliability and quality of these boards, you will find them in some applications.

Automotive

The semi flex PCB plays a vital role in the automotive industry. This PCB is ideal for applications in which there is no dynamic stressing of the bending area. You will find a semi flex PCB in automobile parts. This board helps to design some parts of a vehicle like antilock brakes and airbag systems. Also, automotive engine control systems feature this board.

Industrial electronics

A semi flex PCB can be very useful in producing industrial electronics. Also, this board has enhanced flexibility and high reliability.

Consumer electronics

You will find semi flex PCBs in cell phones and hearing aid devices. The semi flex PCBs play a significant role in the consumer electronics industry.

Medical devices

There are several medical devices that feature semi flex boards. Some of these devices include heart monitoring devices and hearing aid devices.

Telecommunication

The telecommunication industry also relies heavily on the semi flex boards. Also, these boards are available in satellites and GPS trackers.