Single-Sided PCB

What are single sided PCBs

Single sided printed circuit boards are circuit boards with one layer of conducting material on one side of the board, while the other side is used for incorporating different electronic components.

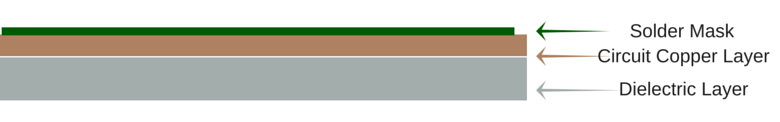

A single sided board is made of a substrate layer, a conductive metal layer and followed by a protective solder mask and silk screen. Single sided circuit boards were the first printed circuit board technology and have been in circulation since the 1950s, and remain one of the most commonly used circuit boards due to their simple design.

Benefits of single sided PCBs

Single sided circuit boards are relatively simple when it comes to their design meaning they require fewer resources and subsequently have a low density. This combination allows for highly cost-effective and affordable manufacturing, as due to their simplicity they can be produced at higher speeds in larger quantities with less potential problems to encounter and without losing the high-quality performance ABL strive to produce. Additionally, this means a shorter lead time for clients as these boards can be produced at speed and in bulk with ease, compared to multi-layer PCBs.

How Are Single Sided PCBs Made?

Benefits Of Single Sided PCBs

- Ideal for simple low-density designs

- Lower cost, especially for high volume orders

- Lower probability of manufacturing issues

- Popular, common, and easily understood by most PCB manufacturers

Matching produces prototype, midrange and high volume Single Sided circuit boards, with a copper thickness from 1 to 20 ounces. Operating temperatures range from 130 C to 230 C. Single sided boards are available with surface finishes including Organic Surface Protectant (OSP), Immersion Silver, Tin, and Gold plating along with both leaded or lead-free Hot Air Solder Level (HASL).

As these circuit boards are straightforward to produce and ideal for simple, low-density designs, this means they are one of the most commonly produced boards. Whilst their design and manufacturing may be simple they can still be used in many complex electronic devices, such as radio and stereo equipment, printers and even vending machines.

Because they can be produced in high quantities, with relatively low production costs, single sided PCBs are the board of choice for many. However, it is important to consider the needs of your project and whether a single sided PCB provides the capabilities and functionalities needed.

If you want to find out more about the best PCB products for you and your project, get in touch with our friendly team here at Matching.

- Power supplies

- Relays (automotive and industrial)

- Timing circuits

- Sensor products

- LED lighting

- Radio and stereo equipment

- Packaging equipment

- Surveillance

- Calculators

- Printers

- Coffee makers

- Vending machines

- Solid state drives

- Camera systems