Detailed Analysis Of The Benefits Of Manufacturing PCB Prototype

Introduction

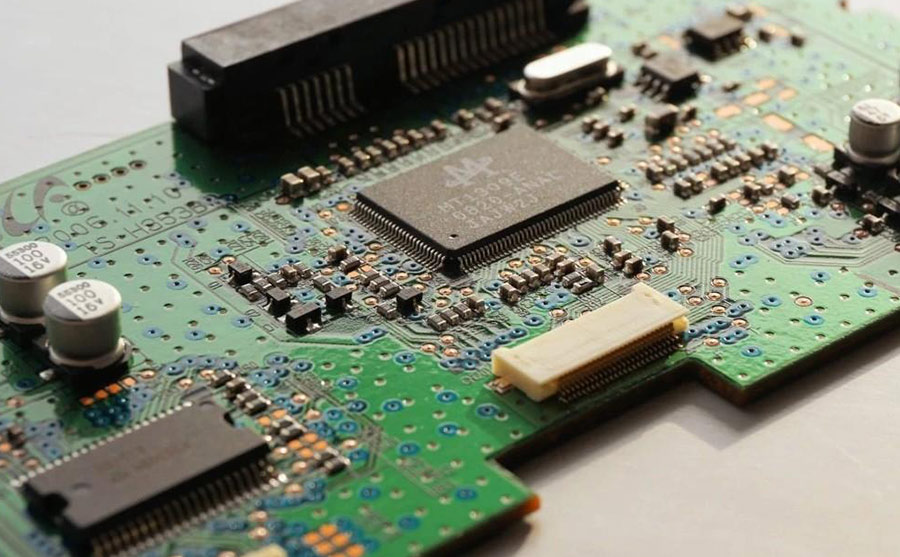

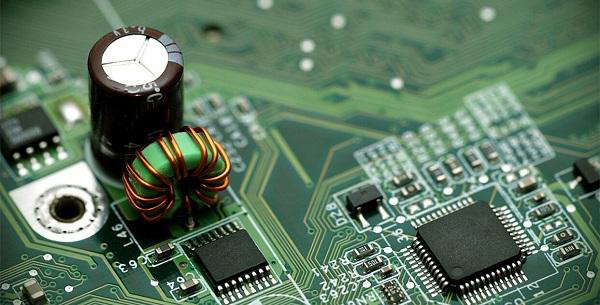

PCB boards are commonly used in most of the appliances around you that you use daily. However, these boards are pretty technical and need a detailed and careful design carried out carefully and free from flaws.

A PCB prototype is, therefore, first manufactured as a testing sample. This allows manufacturers to ensure that the board has no flaws in case any improvement is needed that could be carried out there and then. This saves the time and money spent on manufacturing PCBs in bulk.

No matter how carefully designers design the PCB boards, there might be specific human or technical errors that need to be fixed. Hence, PCB prototypes are first manufactured to address any issues.

What is a PCB prototype?

The PCB prototype is a sample of the actual prototype, which allows for testing the board's functionality and whether it works well with the appliance. Sometimes the prototype could be fully functional, and sometimes it could be just a concept of what an actual PCB would be.

By way of a PCB prototype, the functionality of the design of a PCB could be tested so that any problems, if persisted, may be fixed. Also, in case any improvements are needed in the final PCB could also be made with the help of testing a prototype and assessing the requirement.

The benefits of making PCB prototype

Many reasons compel businesses to make prototypes for the PCB, and then once approved, those prototypes may be subjected to bulk manufacturing. There are various benefits associated with the PCB prototype that lead to consider this choice, some of these are discussed below:

Reduce the production time

Creating a PCB is not a piece of cake; it requires the engineers to go through plenty of details, and after a very lengthy analysis, they are manufactured. However, having the PCB prototypes created at first eliminates the time lags, and relatively very quickly, the PCB designs can be manufactured after the PCB prototype's thorough testing.

The time is saved in various ways by choosing to have a PCB prototype first, and this comprises of the following ways:

● The designers can test the entire design before the whole production run starts. This saves the time of the designers as well as the clients and also the costs involved. If any flaws are present, they will be fixed without wasting time during the final production process.

● Many clients prefer having a look at the design of their prototypes during the process, and since the visual aids allow having a look at the PCB prototype this way, the clients may also assess the design. If they need any changes in these designs, such differences could also be addressed promptly.

● By way of having a prototype designed for PCB, it allows for minimizing the time spent on the final production run. This is because any flaws are identified beforehand rather than during final production. Fixing the spots at the final output is more time taking.

Check the blind spots and defects in the design

Irrespective of the fact that you choose the best design team, there is a chance of minor defects sometimes. A designer who designs an out of the world PCB prototype of one kind might create a prototype of another area with minor imperfections.

So, to identify and fix such blind spots, it becomes easier to have a prototype instead of waiting for the entire production run to take place. This will save time as well as the costs involved in the process.

Accurate and reliable prototype

The final PCB must be defect-free to be used with appliances offering accurate results; this is one of the essential things about PCBs. However, it is equally important to have a precise prototype designed beforehand to achieve this objective.

This will help a lot in manufacturing the final PCB because, by way of a PCB prototype, the designers would be able to identify the flaws in the development stage.

1. PCB design

When the design of the PCB prototype is accurate, the flaw will also be accurately identified. Hence, a precise PCB prototype will help the designers identify the deficiencies during the development stage, which will not only help save time but also reduce cost.

2. Functional testing

There is a vast difference between the theoretical and practical aspects of manufacturing. Similarly, when a prototype is developed, it might have discrepancies between theoretical and practical values, and this issue could be addressed by means of a PCB prototype.

3. Condition testing

It often happens that certain PCBs cannot handle the surrounding environments sometimes. The temperature and environmental conditions do have an impact on their functionality. Hence, a PCB prototype allows insight into this aspect of a PCB and whether it would be sustained in the environment.

4. Final product design

A PCB is fixed inside an appliance, and the design incorporating it must also be checked as much as it is essential to assess the PCB. A prototype will assess whether or not a particular PCB design can be adjusted in the packaging of appliances. If not, the final product might require some changes in the design.

Individual test components

Various components are joined together to create one design. Testing the PCB with such components is imperative to see whether they function properly. Also, sometimes different PCBs are equipped in one appliance, and their synchronization with one another is also required to be tested. Such testing can be assessed easily through a PCB prototype, and issues could be identified if they persist.

Reduce manufacturing cost

The final production runs are always very costly; hence, by choosing to have a PCB prototype beforehand, the flaws would be identified on time and even fixed rightly. Also the adjustments needed on the product could also be made by incorporating the prototypes.

In case there is any flaw in the design, and it is observed at the time of final production, it becomes very costly to discard the PCBs.

Conclusion

To ensure that your appliance works well, it is imperative to have the right PCBs manufactured too. At Matching PCB, you can be assured about the quality of PCB available. We always provide you with a prototype so the testing process can be satisfactory enough for production.

So, choosing us would always be a perfect add-on for you to have your appliances equipped with the best-quality PCBs. These prototypes will help you make an assessment beforehand.